John builds the bronze lantern railing so that we can have an open area and still keep the beacon secure as a US Coast Guard aid to navigation.

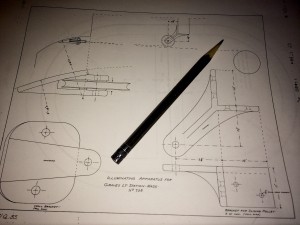

Remember those bronze castings we made over the winter? John and John from Nelson Metal Fabrication machined them to perfection and fitted pickets and rails made up in their Portland, Maine shop.

Then they brought them out to Graves and hoisted them up the ladder and into the lantern room.

Three days later, the results are amazing.

Graves Light remains an active aid to navigation. We have to make sure that while we make as much use as we can of the lantern room, the topmost level of the tower, we have to keep the solar-powered lantern safe and free of obstructions. We also have to make sure it remains accessible to the Coast Guard for their maintenance visits.