Polishing a century of grime from one of the brackets of the original First Order Fresnel lens rotation mechanism.

Ever wonder how the giant First Order Fresnel lens rotated to produce that smooth, sweeping beam lf light?

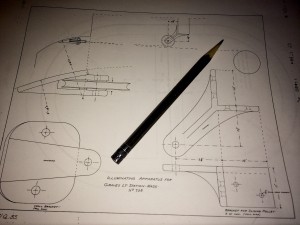

The good guys at the US Coast Guard revealed the secret by sending us the old engineering drawings of parts of the original mechanism, which are still bolted to the 5th level ceiling.

Since that ceiling is being restored, we figured we’d take the mechanism down and clean it up, which we did this week at home.

Here’s how it worked: Every two hours the Keepers wound a 300-lb weight up a 50-foot tube using a hand crank. The weight was connected by a series of pulleys (pictured) and connected to a big clockwork device, which regulated the speed and drove a gear that spun the two-ton lens.

The system was converted to an electric motor long ago, but happily the Coast Guard left all the old stuff in place, which made it possible for us to tell the story.

- Polishing a century of grime from one of the brackets of the original First Order Fresnel lens rotation mechanism.

- The US Coast Guard provided us with this copy of the original drawings of the lamp rotation mechanism.

- Here are some of the parts of the rotation mechanism, (illustrated in the original engineering drawings) as we salvaged them from the 5th floor ceiling.

Dave,

Just want to tell you the refurbishing you are doing

is looking fantastic. To think we will all be able

to look at history being kept and nourished by you

for years to come is very exciting.

Thank you for your hard work please pass this on to

your crew and I hope you and your wife get to have

wonderful times in the house.

Sincerely

Grace and Steve Williams