One of the unsung heroes of the entire Graves Light revival has been our trusty Miss Cuddy I.

Miss Cuddy is a surplus 25-foot US Coast Guard Defender-class boat named after our beloved Monica Cuddy, who taught fourth grade for 40 years in Lynn.

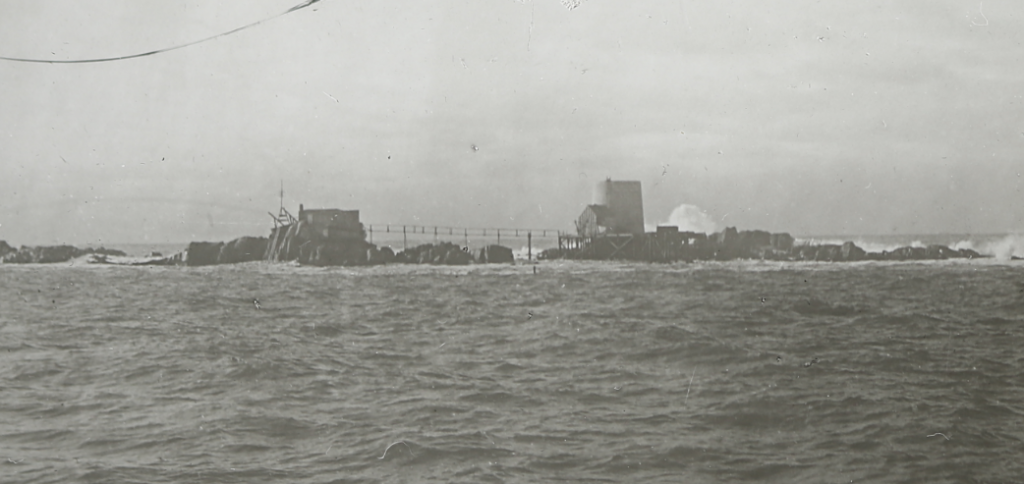

Last fall Miss Cuddy was wrecked when she pulled her mooring block in a gale and smashed up on the dangerous Graves Ledge.

But she didn’t sink!

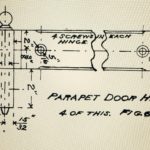

Nelson Metal Fabrication, which was building our footbridge from the lighthouse to the oil house, cut off the cabin and transformed Miss Cuddy into an open decked barge.

Since then, she’s hauled about 19 tons of steel, stone, and timber to supply us with materials for summer projects.

These five pictures show the process.

The two-ton crane at Winthrop Town Pier lowers steel components of the footbridge.

Winthrop Harbormaster Larry and his crew on Miss Cuddy I.

Miss Cuddy II tows Miss Cuddy I on the hour-long haul from Winthrop to Graves.

Miss Cuddy I is fastened at high tide to Graves Ledge to unload her cargo.

Using a big two ton-crane at the Winthrop Town Pier, Harbormaster Larry and his crew gently lower the supplies into her hold. We secure the load and begin the hour long haul to Graves, where we fasten Miss Cuddy tight to the rocks at high tide and pull the supplies using a hoist and cable trolley system designed by Nelson Metals in Maine with Nelson Wire Rope near Philadelphia.

Why such a crazy scheme? Well, due to the topography of Graves Ledge, a traditional crane and barge rig can’t get close enough to set the pilings for the new footbridge, or set the granite blocks for the Oil House.

So we devised a low-impact, greener (much!) method of transport.

At the end of the season, we’ll haul away the scaffolding, tidy up the worksite, and (sniff!) cut up Miss Cuddy for scrap.

Good ol’ Miss Cuddy I!

(Yes, we now have Miss Cuddy II, another Defender-class boat.)

The two-ton crane at Winthrop Town Pier lowers steel components of the footbridge.

Winthrop Harbormaster Larry and his crew on Miss Cuddy I, with a cargo of lumber, plywood, and steel.

Miss Cuddy II tows Miss Cuddy I on the hour-long haul from Winthrop to Graves.

Miss Cuddy I is fastened at high tide to Graves Ledge to unload her cargo.

High and dry as the tide recedes, Miss Cuddy I is unloaded of her cargo that will become the footbridge from the Oil House to the Lighthouse.