The leaky bronze doors on the Watch Deck needed new hinges to create a perfect seal against the weather.

We just couldn’t buy them in a store, or even find antique originals.

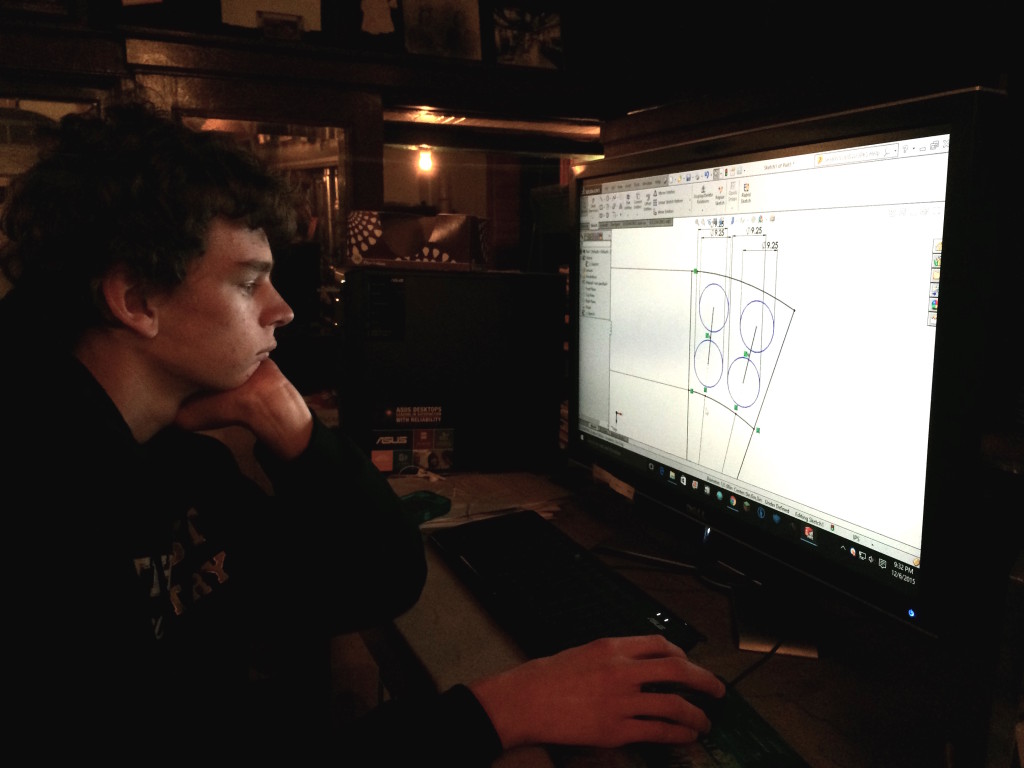

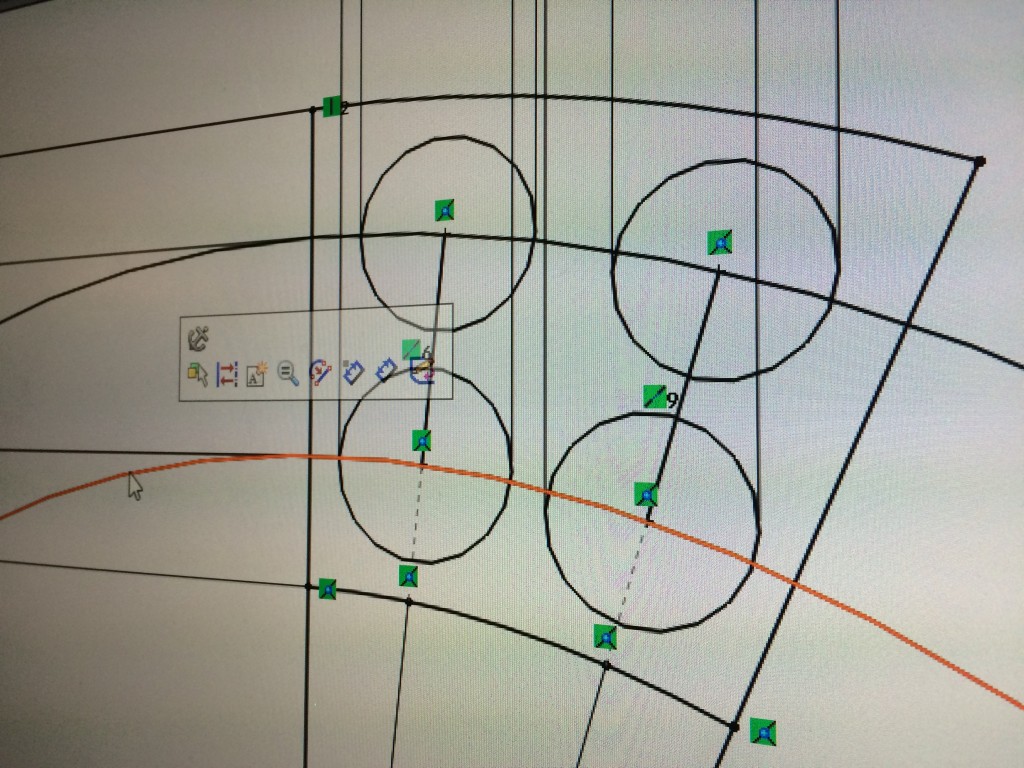

So we went back to the drawing board and used the original architectural drawings of Graves Light from 1903.

Those drawings included sketches and dimensions of the original hinges.

John Nelson of Nelson Metal Fabrication has fixed the leaky doors. John did a lot of great work for us already, and now it was time for more.

Using the original designs as a guide, John machined new stainless hinges to perfectly match the damaged old ones. Now the doors shut tight! The hinges should last until the 22nd century, at least.

- These custom-built stainless steel replacement hinges should last another hundred years.

- The new hinge is in place, painted to match the outside of the Watch Deck door.

- Here’s the Watch Deck (kitchen) door, from the inside.

- The original 1903 architectural drawing was our guide.