Our pal Randy Clark took this nifty shot of master carpenter Karl Phillips sanding the new mahogany railing prior to installing it on the 4th level stairwell.

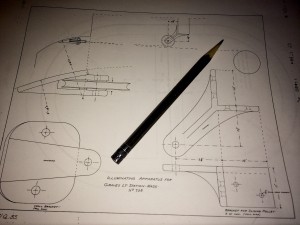

Look closely and you can see some of the work we’ve done:

- Power-washed the stone exterior, which used to be streaked with black soot and grime;

- Replaced the mortar between the stone blocks;

- Removed the block-glass windows and restored the original appearance with oak casement windows (that Karl Phillips built);

- Cleaned and painted the iron railing around the watch deck;

- Cleaned and painted the bronze circular wall, as shown (in black), on the watch deck;

- Installed vintage brass portholes in the bronze wall of the watch deck, to provide natural light in the interior;

- Cleaned and re-caulked the original curved glass panes of the lantern deck;

- Installed an exact replica of the interior mahogany staircase railings (which Karl is shown sanding on the outside deck).

A photographer by trade, Randy also swung a hammer to fix the shed while piloting his new drone. Thanks Randy!