At his Nantucket shop, Karl Phillips works on the new oak ceiling of the 5th floor of Graves Light – a perfect copy of the ruined original.

We’re getting wicked excited about a winter project that’s entering its final stages.

The oak ceiling of the Graves Light living quarters are being reconstructed, just as it would have looked in 1905.

Down on Nantucket, Driftwood Construction’s own Karl Phillips is working day and night, this time building the amazing paneled oak ceiling for the 5th floor study.

Karl already built perfect oak copies of the original casement windows, window sills, window paneling, and interior stairway doors.

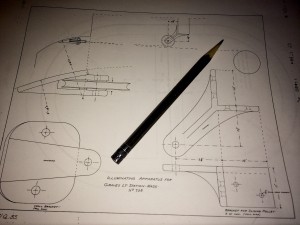

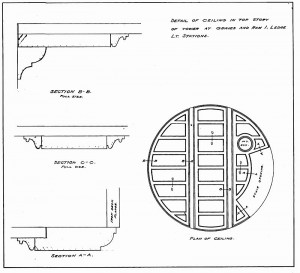

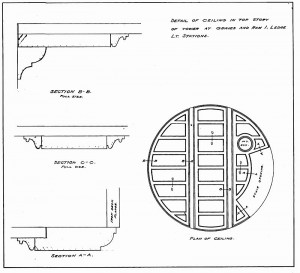

He’s been using the original 1903 architectural drawings to rebuild the ceiling. But since parts of the original ceiling are still in place (despite their heavy damage), Karl was able to take measurements right off the original.

For the fun of future generations, we think we’ll install this new ceiling to cover the original old one, so that in another 100 years, people will have something to discover.

Take a look at the pictures of Karl’s latest work.

-

-

At his Nantucket shop, Karl Phillips works on the new oak ceiling of the 5th floor of Graves Light – a perfect copy of the ruined original.

-

-

The 5th floor oak ceiling comes together at Karl’s Nantucket shop.

-

-

The ceiling is 13 feet in diameter, made of white oak.

-

-

This is what we found of the original ceiling before we began renovation.

-

-

This is the original 1903 US Light House Service architectural drawing for the oak ceiling.